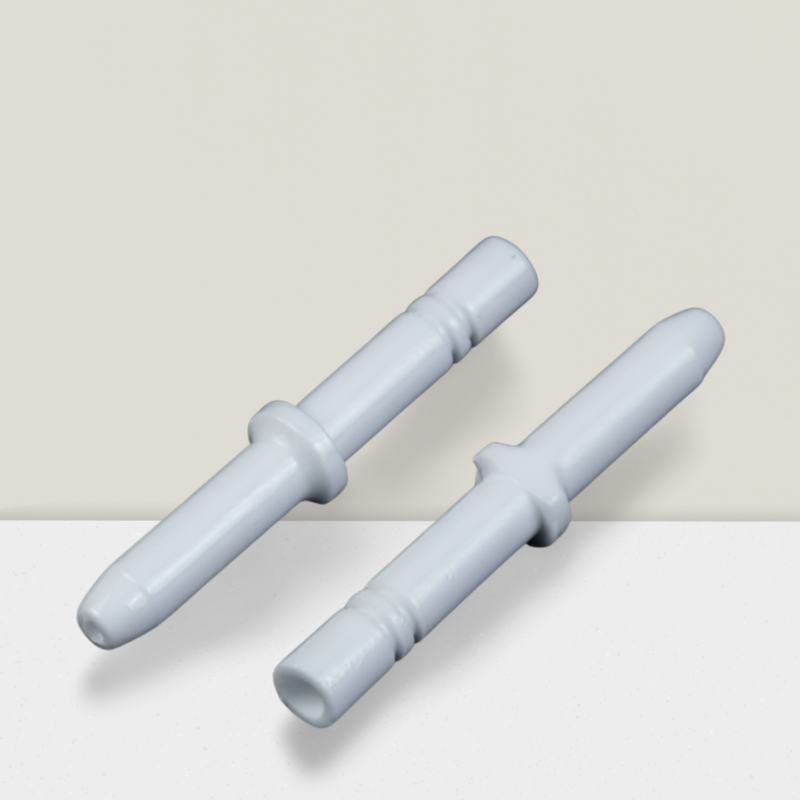

Semiconductor alumina ceramic robot hand arm

Ceramic robotic arm

It’s known as the ceramic carrying arm, plays a transporting role in semiconductor equipment. It is equivalent to the hand of the robot in semiconductor equipment and is responsible for carrying wafers and silicon wafers to designated locations. Because silicon wafers are extremely susceptible to contamination from other particles, they are generally carried out in a vacuum environment.

There are generally two types of ceramic robot arms, one is an alumina ceramic robot arm, and the other is a silicon carbide ceramic robot arm.

Both have the physical properties of density, high hardness, and high wear resistance, as well as good heat resistance, excellent mechanical strength, good insulation in high temperature environments, and good corrosion resistance. They are used Excellent material for manufacturing robotic arms for semiconductor equipment.

Properties | Units | 95% | 99% | 99.5% Al2O3 |

Colour | White | Ivory | Ivory | |

Density | g/cm3 | 3.5 | 3.85 | 3.9 |

Flexural Strength | Mpa | 280 | 340 | 350 |

Compressive Strength | MPa | 2100 | 2200 | 2350 |

Max Use Temperature | °C | 1400 | 1650 | 1650 |

Thermal Condutivity | W/m.K | 16~28 | 19~30 | 19-31.4 |

Thermal Expansion Cofficient | 10-6/°C | 6.5~7.5 | 6~8 | 8 |

Thermal Shock Resistance | K | 150 | 150 | 200 |

Specific Heat | J/kg.K | 950 | 950 | 950 |

Dielectric Strength | KV/mm | 10 | 12 | 18 |

Dielectric Constant | Er | 9 | 9 | 10 |