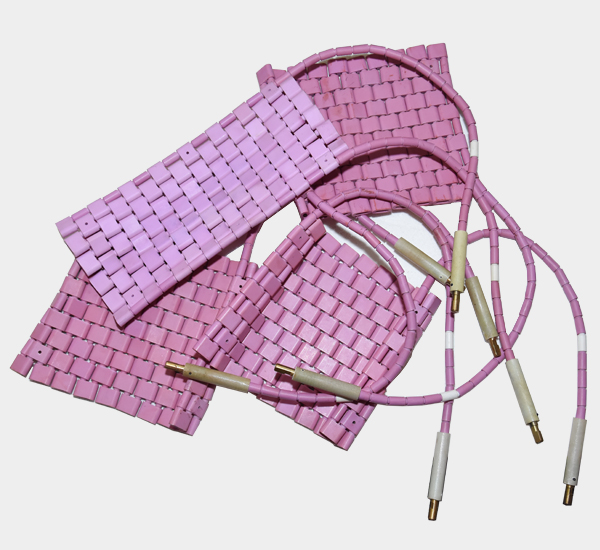

Alumina ceramic and zirconia ceramic labware crucibles

Alumina Crucible Description

Alumina Crucibles from Advanced Ceramic Materials are crafted from high-purity Al2O3. With low thermal expansion, alumina is ideal for furnace use in crucibles, tubes, and thermocouple sheaths. Additionally, its high hardness and wear resistance make it suitable for applications such as ball valves, piston pumps, and deep drawing tools.

Alumina Crucible Applications

Alumina crucibles are used in various applications, including:

- Semiconductor Industry: Parts for CVD, ion implants, photolithography, and other semiconductor parts.

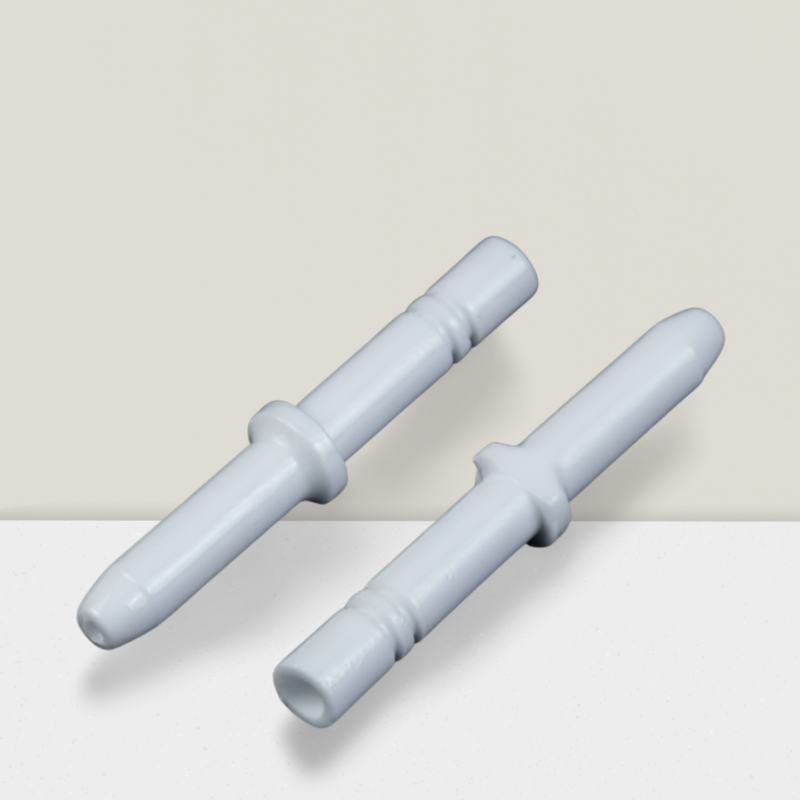

- Traditional Industries: Ideal for injector tubes, gas nozzles, and insulators.

- Industrial Furnaces: Maintains hardness at high temperatures, making it perfect for industrial furnaces.

- Thermocouple Protection: Acts as a protector for high-temperature thermocouples.

- Chemical Industry: High corrosion resistance makes it suitable for chemical processing equipment.

Properties | Units | 95% | 99% | 99.5% Al2O3 |

Colour | White | Ivory | Ivory | |

Density | g/cm3 | 3.5 | 3.85 | 3.9 |

Flexural Strength | Mpa | 280 | 340 | 350 |

Compressive Strength | MPa | 2100 | 2200 | 2350 |

Max Use Temperature | °C | 1400 | 1650 | 1650 |

Thermal Condutivity | W/m.K | 16~28 | 19~30 | 19-31.4 |

Thermal Expansion Cofficient | 10-6/°C | 6.5~7.5 | 6~8 | 8 |

Thermal Shock Resistance | K | 150 | 150 | 200 |

Specific Heat | J/kg.K | 950 | 950 | 950 |

Dielectric Strength | KV/mm | 10 | 12 | 18 |

Dielectric Constant | Er | 9 | 9 | 10 |