Ceramic cores immersion heater

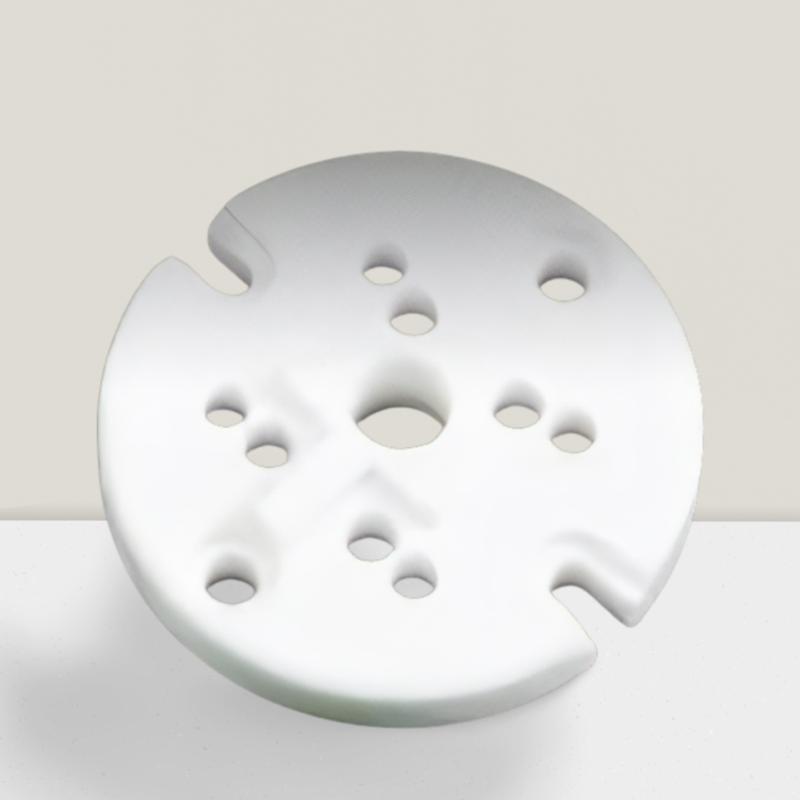

Ceramic core immersion heaters consist of a high temperature ceramic former that then has a spiralled resistance wire coil running through a number of holes along the length of the former.

These formers are then joined together to give the customers required heated length. Generally then a central stainless steel tie bar locks all the formers together.

Properties | Units | Steatite | Cordierite | Mullite |

Colour | White | Yellow | White | |

Density | g/cm3 | 2.7 | 1.9 | 2.0 |

Flexural Strength | Mpa | 140 | 30 | 120 |

Compressive Strength | MPa | 900 | 350 | 500 |

Max Use Temperature | °C | 1000 | 1200 | 1300 |

Thermal Condutivity | W/m.K | 2~3 | 1.3~1.8 | 2~6 |

Thermal Expansion Cofficient | 10-6/°C | 7 ~ 9 | 1.5~3.5 | 5~6 |

Thermal Shock Resistance | K | 100 | 300 | 150 |

Specific Heat | J/kg.K | 850 | 800 | 900 |

Dielectric Strength | KV/mm | 20 | — | 30 |

Dielectric Constant | Er | 6 | — | 8 |

Related products

-

Cordierite/Mullite

Ceramic terminal heads

-

Cordierite/Mullite

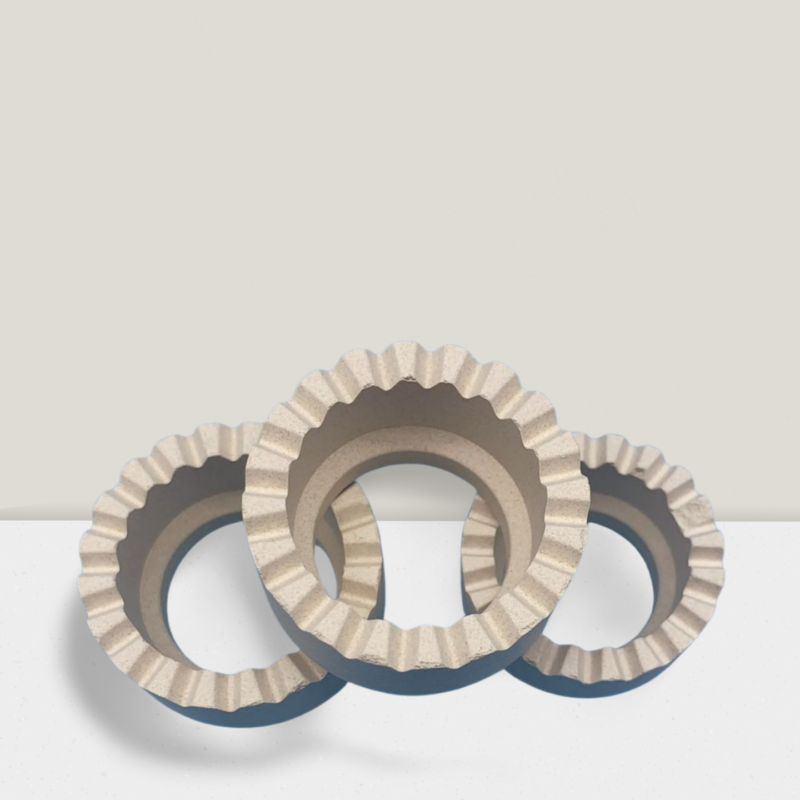

Cuplocks type anchors Ceramic cuplocks high temperature insulation parts

-

Cordierite/Mullite

Cordierite ceramic ferrules for stud welding

-

Cordierite/Mullite

Ceramic arc shields shear stud ferrules