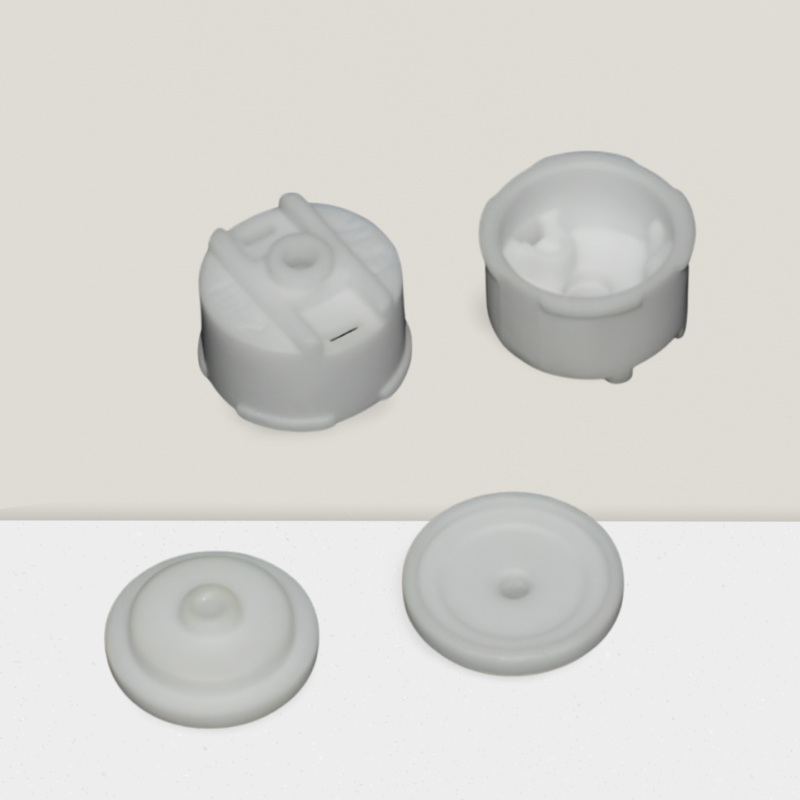

Ceramic steatite alumina bush

Ceramic bush, or ceramic sleeve, finds its applications in a wide range of industries and scenarios owing to its outstanding properties such as high hardness, wear resistance, corrosion resistance, and thermal stability.

Application:

- Mechanical Engineering: Ceramic bush is often used in sliding or rotating components that require high precision and longevity, such as bearings, gearboxes, and transmission shafts.

- Petrochemical Industry: In the petrochemical sector, ceramic bush is widely applied in valves, pump bodies, and pipelines due to its superior corrosion resistance and high-temperature tolerance.

- Aerospace: The aerospace industry demands materials with exceptional properties, and ceramic bush meets these requirements due to its lightweight, high strength, high-temperature resistance, and radiation resistance. It is commonly used in critical components of aircraft engines, rocket engines, and satellites.

- Medical Devices: In the medical field, ceramic bush is employed in the manufacture of key components for artificial joints, dental implants, and other medical devices. Its good biocompatibility and wear resistance make it an ideal choice for these applications.

- Electronics Industry: Ceramic bush is also utilized in the electronics industry, particularly in high-frequency circuits, microwave devices, and integrated circuits.

- Other Industries: Additionally, ceramic bush may find applications in textiles, printing, food processing, and other industries where its wear resistance, corrosion resistance, and self-lubricating properties can significantly improve equipment efficiency and lifespan.

Properties | Units | Steatite | Cordierite | Mullite |

Colour | White | Yellow | White | |

Density | g/cm3 | 2.7 | 1.9 | 2.0 |

Flexural Strength | Mpa | 140 | 30 | 120 |

Compressive Strength | MPa | 900 | 350 | 500 |

Max Use Temperature | °C | 1000 | 1200 | 1300 |

Thermal Condutivity | W/m.K | 2~3 | 1.3~1.8 | 2~6 |

Thermal Expansion Cofficient | 10-6/°C | 7 ~ 9 | 1.5~3.5 | 5~6 |

Thermal Shock Resistance | K | 100 | 300 | 150 |

Specific Heat | J/kg.K | 850 | 800 | 900 |

Dielectric Strength | KV/mm | 20 | — | 30 |

Dielectric Constant | Er | 6 | — | 8 |

Related products

-

Steatite

Ceramic standoff insulators

-

Steatite

Ceramic base for thermostat switch