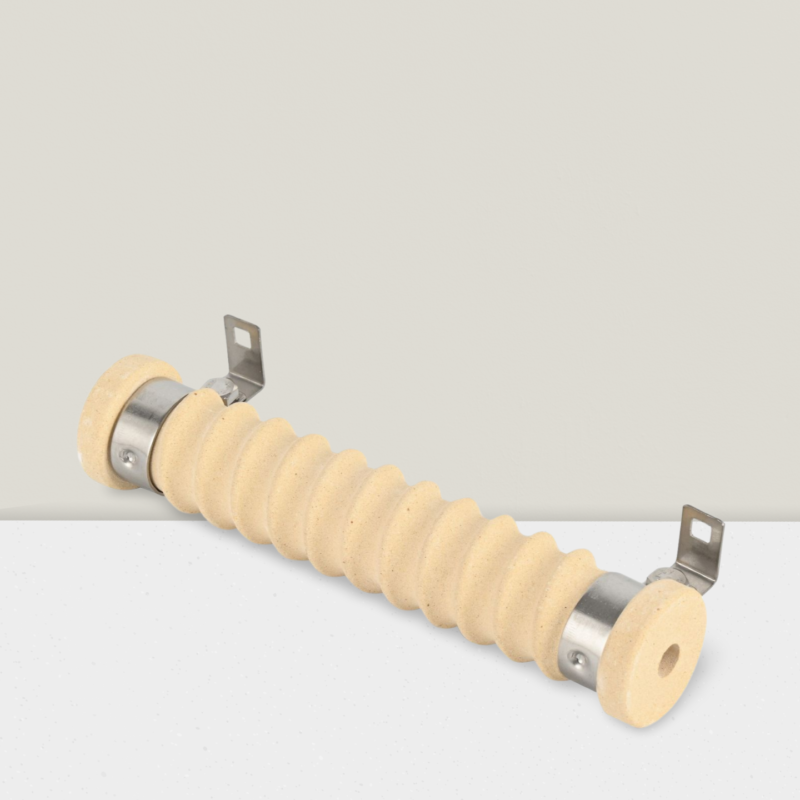

Ceramic support for hot air gun heater heating element

Ceramic support for hot air gun heater heating element

Heating element spare parts ceramic support ceramic bracket

A ceramic bracket and heating core technology, applied in the direction of heating elements, ohmic resistance heating parts, etc., can solve the problems of uneven temperature of the resistance wire, extending the service life of the heating wire, and the inability to carry out the heat of the heating wire, etc., to achieve the goal of increasing the temperature effect.

Our ceramic brackets can be specifically applied in the following heating products:

- Fish tank heaters: Ceramic heaters are a common choice for heating fish tanks, utilizing the excellent thermal conductivity and stability of ceramics to provide a safe and constant temperature environment for the fish tank.

- LED lighting heat dissipation brackets: In LED lighting, ceramic brackets are often used to encapsulate LED light sources, especially integrated COB(Chip on board)light sources, due to their outstanding thermal conductivity and insulating properties, thereby improving the heat dissipation performance and safety of the lighting.

- Household applicance heating elements: Ceramic brackets can alse be used in various household applicances such as electric soldering irons, electric irons, and fan heaters, serving as the supporting structure for heating elements to ensure heating efficiency and safety.

- Industrial heating equipment: Ceramic brackets are suitable for use in various heating equipment such as ovens and furnaces, thanks to their high temperature resistance and corrosion resistance, making them an ideal choice.

- Medical device heating elements: In medical devices such as infrared therapy instruments and intravenous infusion heaters, ceramic brackets also play an important role in ensuring precise temperature control and safety performace of the devices.

Properties | Units | Steatite | Cordierite | Mullite |

Colour | White | Yellow | White | |

Density | g/cm3 | 2.7 | 1.9 | 2.0 |

Flexural Strength | Mpa | 140 | 30 | 120 |

Compressive Strength | MPa | 900 | 350 | 500 |

Max Use Temperature | °C | 1000 | 1200 | 1300 |

Thermal Condutivity | W/m.K | 2~3 | 1.3~1.8 | 2~6 |

Thermal Expansion Cofficient | 10-6/°C | 7 ~ 9 | 1.5~3.5 | 5~6 |

Thermal Shock Resistance | K | 100 | 300 | 150 |

Specific Heat | J/kg.K | 850 | 800 | 900 |

Dielectric Strength | KV/mm | 20 | — | 30 |

Dielectric Constant | Er | 6 | — | 8 |

Related products

-

Cordierite/Mullite

Ceramic cores immersion heater

-

Cordierite/Mullite

Ceramic arc shields shear stud ferrules