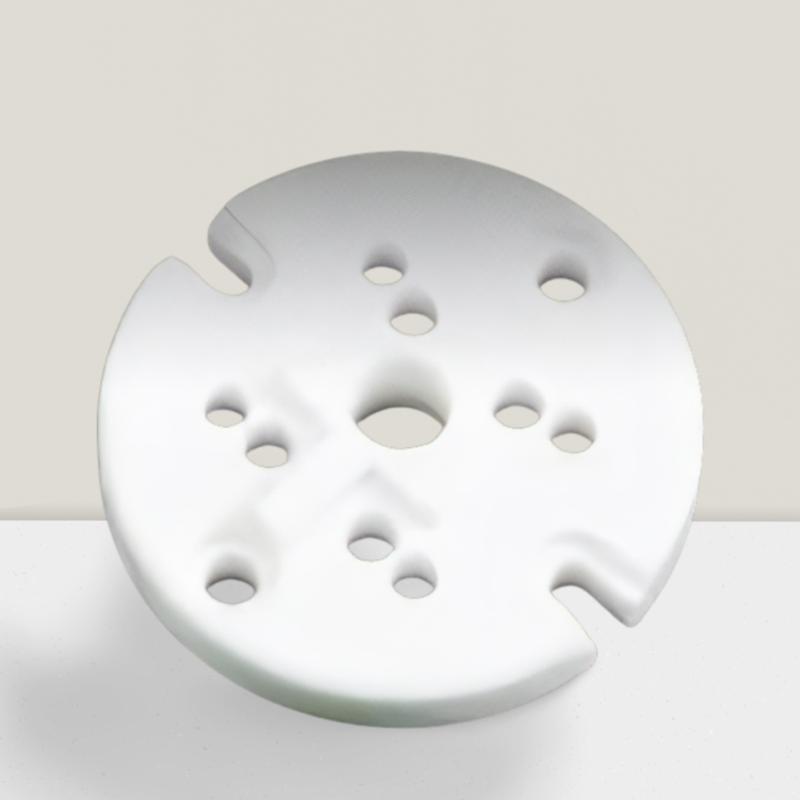

Electric heating ceramic supports used for hair dryer

Electric heating ceramic supports used for hair dryer

Material of ceramic supports: Cordierite or Mullite

Size: Support OEM

Description:

The process flow for manufacturing hair dryers using ceramic supports and wound heating elements mainly includes the following steps:

1.Material Preparation: Ceramic supports, heating elements (electric wires), insulating materials, connecting wires, etc.

2.Fixing One End of the Heating Element: Fix one end of the heating element to one side or a specific position on the ceramic support.

3.Winding the Heating Element: Using mechanical or manual methods, wind the heating element evenly onto the ceramic support to form a specific shape (such as a spiral).

4.Cutting the Heating Element: After winding the heating element fully around the ceramic support, remove the wound heating element and cut it into multiple sections according to actual usage requirements.

5.Installing the Heating Element: Wind the cut heating element segments onto the insulating mold core of the hair dryer’s air cylinder, ensuring that the connection between the heating element and the ceramic support is stable, while maintaining a uniform spacing between the heating element segments.

6.Connecting the Circuit: Use connecting wires to connect the heating element to the power circuit of the hair dryer, ensuring that the circuit connections are correct and safe.

7.Testing and Adjustment: Conduct a power-on test on the wound heating element to check if the heating effect is uniform and if there are any short circuits, open circuits, or other issues. Make necessary adjustments and optimizations based on the test results.

Material of ceramic supports: Cordierite or Mullite

Size: Support OEM

Properties | Units | Steatite | Cordierite | Mullite |

Colour | White | Yellow | White | |

Density | g/cm3 | 2.7 | 1.9 | 2.0 |

Flexural Strength | Mpa | 140 | 30 | 120 |

Compressive Strength | MPa | 900 | 350 | 500 |

Max Use Temperature | °C | 1000 | 1200 | 1300 |

Thermal Condutivity | W/m.K | 2~3 | 1.3~1.8 | 2~6 |

Thermal Expansion Cofficient | 10-6/°C | 7 ~ 9 | 1.5~3.5 | 5~6 |

Thermal Shock Resistance | K | 100 | 300 | 150 |

Specific Heat | J/kg.K | 850 | 800 | 900 |

Dielectric Strength | KV/mm | 20 | — | 30 |

Dielectric Constant | Er | 6 | — | 8 |

Related products

-

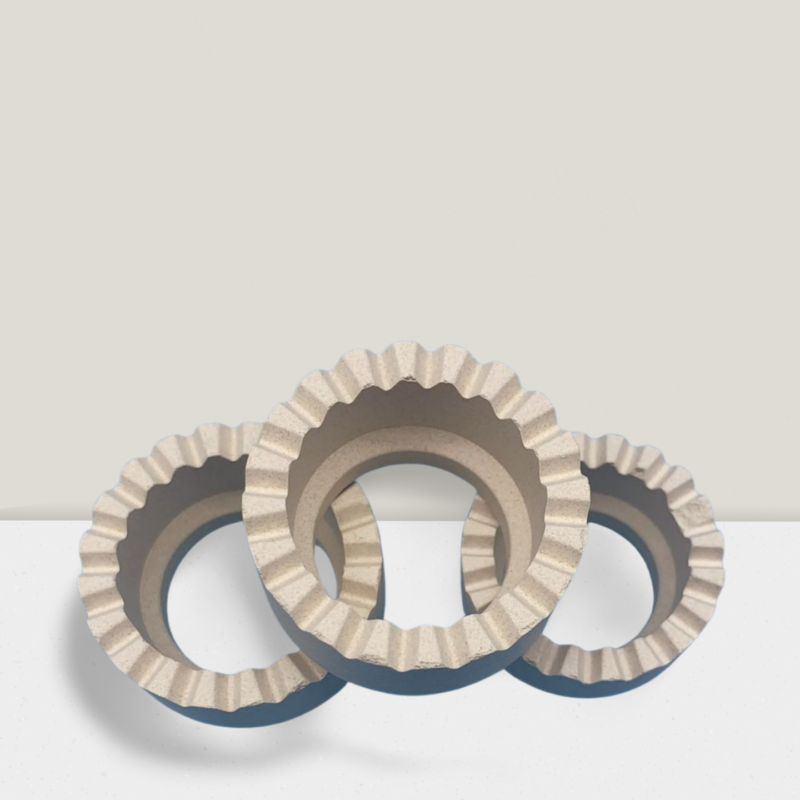

Cordierite/Mullite

Ceramic terminal heads

-

Cordierite/Mullite

Cordierite ceramic ferrules for stud welding

-

Cordierite/Mullite

Ceramic arc shields shear stud ferrules